Manufacturing process

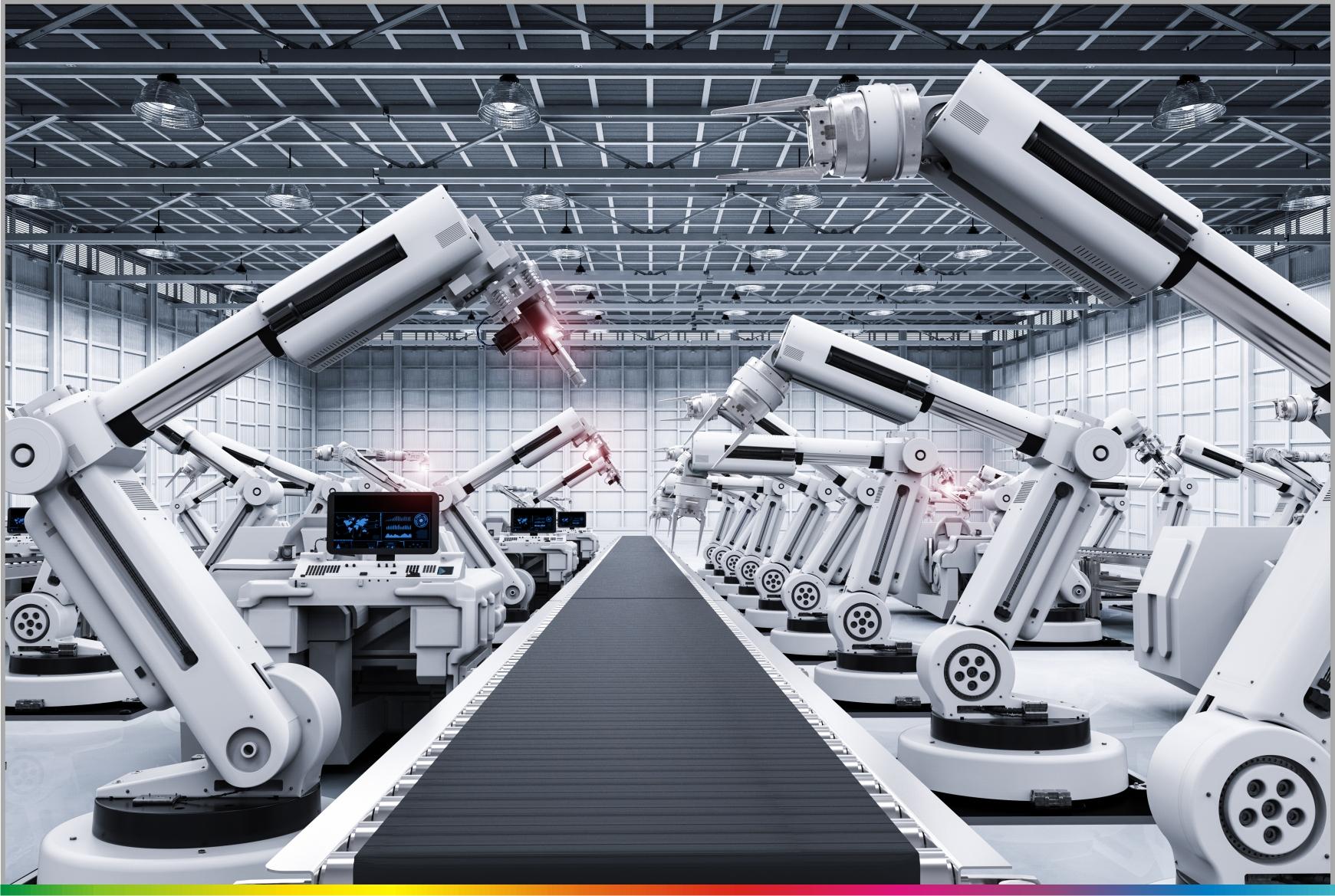

An optimized manufacturing process is crucial to the success of both Noex, as a company, and its clients, who we provide our services to. Plastics, which we process, are used in the manufacturing of various types of elements, including machinery components or everyday items. Their efficient processing requires planning each manufacturing process stage and involves the application of advanced technologies.

An optimized manufacturing process is crucial to the success of both Noex, as a company, and its clients, who we provide our services to. Plastics, which we process, are used in the manufacturing of various types of elements, including machinery components or everyday items. Their efficient processing requires planning each manufacturing process stage and involves the application of advanced technologies.

Manufacturing process stages

The first stage involves designing a mould, which is a shape that is to be created using a specific plastic. To this end we use specialized computer software that enables developing a 3D item model. The next step is to set up an injection moulding machine and appropriate ingredients. Then, the plastic, at an appropriate temperature and pressure, is injected into the ready mould.

The first stage involves designing a mould, which is a shape that is to be created using a specific plastic. To this end we use specialized computer software that enables developing a 3D item model. The next step is to set up an injection moulding machine and appropriate ingredients. Then, the plastic, at an appropriate temperature and pressure, is injected into the ready mould.

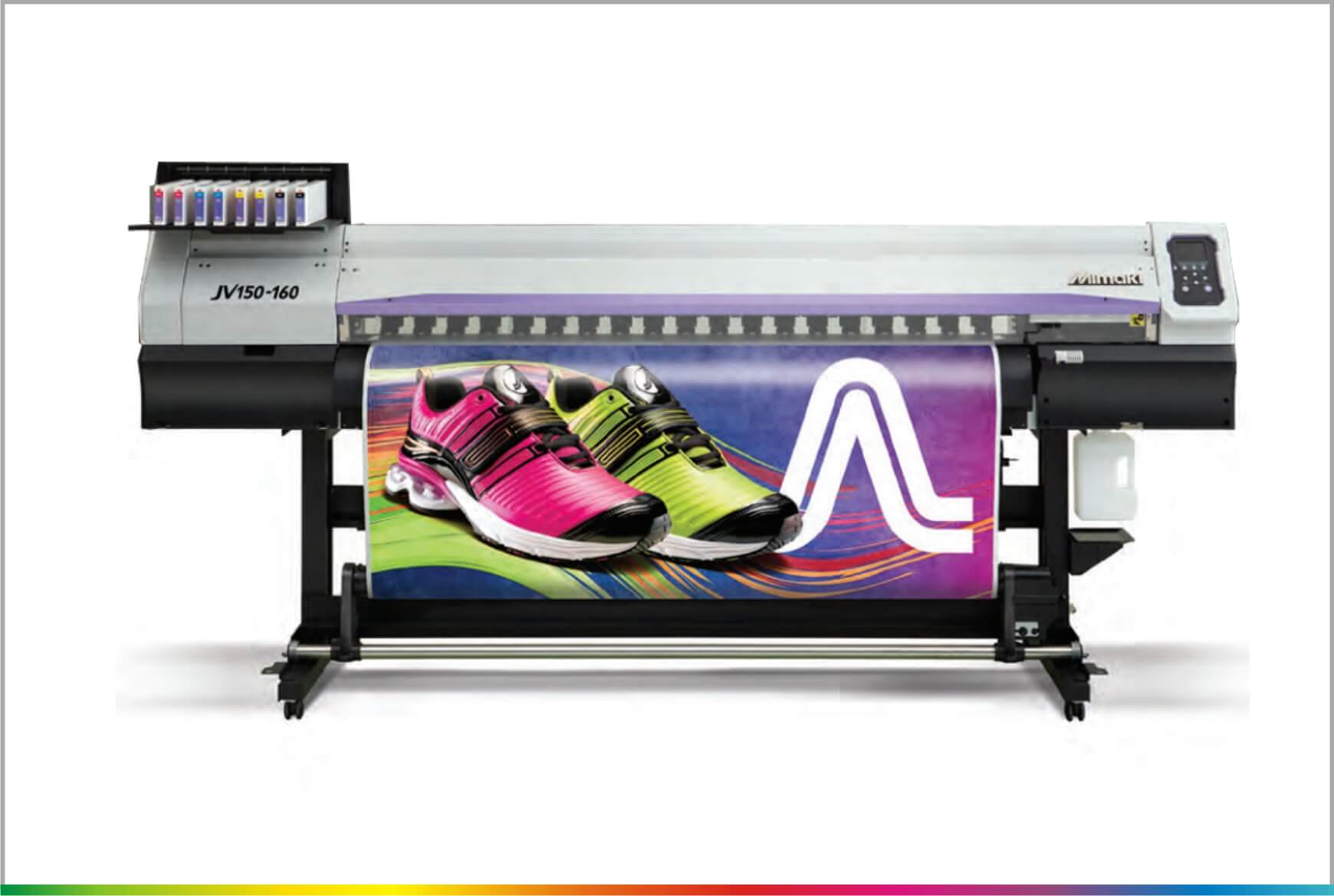

The fourth stage is assembling elements into a finished product. For the process to run smoothly, it requires trained employees and machines facilitating trouble-free installation. Next, product batches are packaged, wrapped and labelled with appropriate information. The last stage is the logistics, which involves coordinating processes related to storage, transport and distribution of finished products.

PRODUCT ASSEMBLY • FILLING AND PACKAGING

• PACKAGING • LOGISTICS