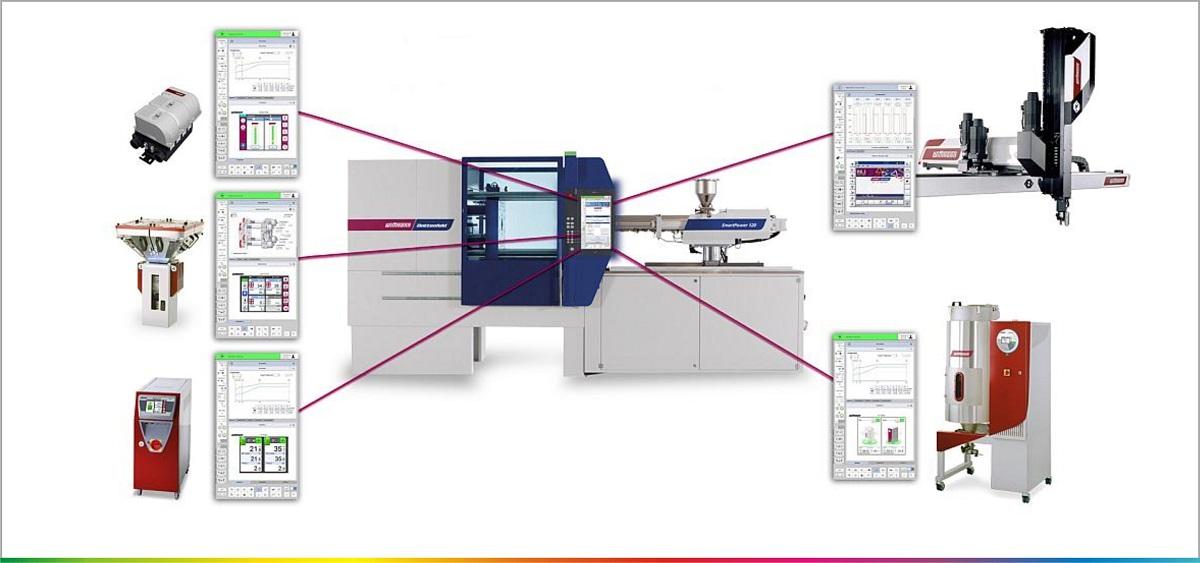

By choosing Noex, you gain access to a state-of-the-art plastic injection moulding facility that can transform your visions into finished, precise products. Our machinery ensures efficiency and reliability, essential for handling both large-scale orders and unique prototypes. Equipped with technologically advanced injection moulding machines and complementary accessories, we are able to meet the most demanding specifications, ensuring the highest quality in detail execution. Regardless of the batch size, perfection is our priority, on which the success of your project depends.

We are your partner in creating perfect injection moulds for plastic, which are the foundation of every successful project. We offer comprehensive service – from consulting, through design, to manufacturing an injection mould perfectly suited to your product’s specifics. You can commission production using both standard molds and fully customized tools that we will create for you. This ensures that every element, regardless of its complexity, is produced with surgical precision, ensuring repeatability and cost optimization of production. Reliable injection moulds for plastic are key to your success.

Our plastic injection moulding service offers flexibility and innovation that drive your business. With our diverse machinery park, we efficiently process raw materials with various properties – from standard polymers to specialized blends. We ensure full customization of the final product to your requirements, including individual color selection, precise marking, and the use of special purifying substances. This opens up almost limitless possibilities – from high-quality products for the advertising industry, such as bar trays, to specialized laboratory containers. With us, moulds for plastic injection become a tailored process.

Choosing us as your producer of moulding injection forms, you gain a partner who takes full responsibility for the quality and functionality of your future products. We design plastic components in full scope – from selecting the optimal manufacturing method, refining the shape and material, to ensuring the expected functionality of the final detail. Our knowledge and experience allow us to create injection moulds for plastic that are synonymous with durability and efficiency. Whether you need support in mass production or seek an innovative solution for a prototype, our team will provide professional advice and execution at the highest level. We are proud to be an experienced producer of moulding injection forms.

Our Plastic Injection Moulding Services give you a competitive edge due to the speed and precision of order fulfillment. With full control over the process – from mold design to final plastic injection moulding – we guarantee that every produced element will meet your expectations in terms of features, parameters, shape, and purpose. Our attention to detail ensures that finished products, such as special laboratory containers or bar trays, stand out in the market for their quality. Fully leverage our plastic injection moulding services for your success. Trust us as your injection mould manufacturer.

How do you control the quality of details during the injection moulding process?

High quality is our priority. We employ advanced control and measurement systems that monitor key injection parameters in real-time. Finished details undergo rigorous tests and dimensional inspections, ensuring that every product leaving our facility is crafted with the highest precision, according to the approved technical specification.

What support can I expect when choosing the plastic for my product?

Our team of engineers will help you select the perfect polymer (or composite) considering not only costs but primarily the intended use of the product, its strength requirements (mechanical, thermal, chemical), and the need for purifying substances. Our goal is to ensure that your product performs optimally.

What are the minimum and maximum sizes of details you can produce in your injection moulding facility?

Thanks to the diversity of our machinery, we can handle projects of very different sizes. From precise, miniature components to larger structural elements. To precisely determine whether your project fits within our production range, please contact us with the specifications – this way, we will select the optimal injection moulds for plastic and machinery.